PRODUCT DESCRIPTION

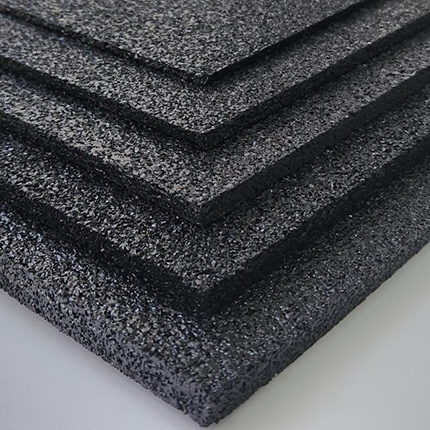

A premium acoustic underlay designed to solve noise transmission while providing optimal sound reduction and durability.

Introducing Terrac Acoustic Rubber Underlays an effective solution to combat unwanted noise transmission in multi-storied buildings. Made using recycled rubber granules, Terrac is designed to reduce both airborne and impact sounds (like speech, loud music, footsteps, structural noise, and more) without compromising on durability or resilience. Available in easy-to-handle rolls and in different thickness options, Terrac is extremely simple to install and is the clear choice for noise reduction in any space. Experience the difference with Terrac Acoustic Rubber Underlays.

High Mechanical

Strength

Mold & Fungus

Resistant

Environment

Friendly

BENEFITS OF TERRAC ACOUSTIC UNDERLAY

LAYERING

TERRAC ACOUSTIC UNDERLAY APPLICATIONS

Terrac® Eco | Soundproofing for Highrises

Terrac® Eco is used for soundproofing in high-rise buildings to enhance residents' comfort and well-being. This acoustic underlay helps address challenges such as noise from other units, outside traffic, and construction.

Technical Data Sheets

Terrac® Prime | Impact Absorption for Gym and Sports

Terrac® Prime is an acoustic underlay used beneath sports tracks for comfort and performance. It absorbs impact, cushioning athletes' joints and muscles during high-impact activities. It minimizes noise from foot traffic and equipment, ensuring a quieter environment. Terrac® underlay improves stability and performance, providing a level and smooth playing surface. It's suitable for use under various sports court surfaces, including wood, vinyl, and other synthetic materials.

Technical Data Sheets

Terrac® Performance | Acoustic Underlay for Industries

Terrac® Performance - Ideal for industrial settings, this acoustic underlay mitigates noise and vibrations. It’s also perfect for soundproofing studios and movie theatres, preventing sound leakage and ensuring clear recordings and an immersive viewing experience.

Technical Data Sheets

Terrac® Acoustic Cradles | Versatile, Easy to Use

Introducing Terrac® Acoustic Cradles - An effective solution for raised / acoustical / sports floorings. Made using recycled rubber granules. These eco-friendly cradles ensure precise and rapid on-site levelling, accommodating various floor coverings and finished heights. The Terrac® Cradles offers top-notch performance for acoustic and sports flooring, with easy on-site adjustment. perfect for raised flooring, sports flooring, new building projects, and refurbishment projects.

Technical Data Sheets

Terrac® PET Panels | Sleek, Modern, Sustainable

Introducing Terrac® PET Panels - Upgrade your spaces with our high-quality PET panels, crafted from recycled Polyethylene Terephthalate (PET). These panels are lightweight, durable, and offer excellent sound absorption, making them perfect for both residential and commercial settings. With a sleek, modern finish and eco-friendly composition, PET panels are an outstanding choice for those seeking style and sustainability. Ideal for wall coverings, partitions, and creative designs, they're easy to install and maintain. Transform your environment effortlessly with PET panels - where functionality meets elegance!

Technical Data Sheets

Certifications

STANDARDS

Certifications

tested by

certified by

tested by

STANDARDS

certified by

certified by

certified for

Deformability/Elasticity, Permanent Tread Load, Abrasion, Slip resistance, Acid resistance

& shot density test by CFR