Whether you’re a gym-from-home person or building a gym for personal or professional goals, having the right flooring in your workout space can make a huge difference in your safety and your equipment’s longevity.

Let’s understand what to consider when deciding how thick your gym flooring should be.

Firstly, why Is Rubber Gym Flooring So Important?

Before we get into the specifics of thickness, it’s important to understand why rubber gym flooring is such a popular and important choice for workout spaces. Here are a few reasons:

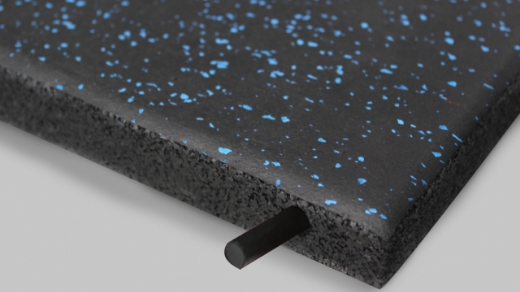

- Durability: Rubber is an incredibly durable material that can withstand the wear and tear of heavy gym equipment, as well as foot traffic and dropped weights.

- Shock absorption: The natural bounce and shock absorption of rubber flooring can help to protect your joints and reduce the risk of injury from high-impact exercises.

- Noise reduction: Rubber flooring can help to absorb noise and vibrations, making for a quieter and more pleasant workout environment.

- Easy maintenance: Rubber flooring is easy to clean and maintain,saving you time and money in the long run.

Now that we know why rubber gym flooring is popular, let’s explore how thick it should be for your specific needs.

Factors to Consider When Choosing Gym Flooring Thickness

- Equipment weight: One of the primary factors to consider when choosing the thickness of your gym flooring is the weight of your equipment. Heavier equipment, such as squat racks or weight machines, will require thicker flooring to prevent damage to both the equipment and the subfloor beneath.

- Type of exercise: The type of exercise you’ll be doing also plays a role in determining the appropriate flooring thickness. High-impact exercises, such as jumping or plyometrics, will require thicker flooring to provide adequate shock absorption and protect your joints.

- Subfloor: The type and condition of your subfloor can also impact the thickness of your gym flooring. If your subfloor is uneven or prone to movement, you may need thicker flooring to ensure a stable surface for your equipment.

So, How Thick Should Your Gym Flooring Be?

Now that we’ve explored some key factors to consider, comes the time for an answer. The answer, unfortunately, isn’t a one-size-fits-all solution.

A thickness of 8mm to 10mm is sufficient for most home gyms. This thickness is suitable for light to moderate use and adequately protect your equipment and subfloor.

However, if you have heavier equipment or plan to do high-impact exercises, you may want to consider thicker flooring. For commercial gyms or other high-traffic areas, thicknesses of up to 15mm or more may be necessary to ensure durability and safety.

In general, it’s always better to err on the side of caution and choose slightly thicker flooring than you think you need. This will help to ensure that you have a stable and safe surface for all of your workouts, and will help to protect your equipment and subfloor from damage over time.

All our rubber tiles are made using European-quality materials at our state-of-the-art factory in the UAE. To learn more about our Terrain rubber flooring products and our other solutions for businesses, industries, and schools, visit www.terrainfloorings.com or give us a call at (+971 4 263 2332).